how to conduct a brinell hardness test|brinell hardness testing procedure : agencies Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition . WEBDEPORTELIBRE - TyC Sports - Mirá en vivo TyC Sports. Disfruta de todo el contenido de TyC Sports en vivo de forma gratuita en tu celular o computadora a través de .

{plog:ftitle_list}

web7,229 likes, 108 comments - gabrielvittorreal on December 6, 2023: "Natal chegando aí ne"

There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method. Non-Standard Method. Standard Brinell Hardness Test: Brinell Indentation Diagram.

The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .The Brinell test is often carried out instead of or alongside Rockwell hardness testing and/or Vickers testing. You can find out more about this alternative method in our guide to Rockwell .

Description of the Brinell hardness test showing the tester, the microscope for measurement and analysis using a spread sheet. Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .

Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison . EN ISO 6506-1 is a European standard that specifies the requirements for metallic materials' Brinell hardness testing. It outlines the testing method, equipment, calibration, .Surface preparation. Before the sample material is placed in the Brinell hardness test unit, it must be either: Machined. Ground. Lapped. Polished. Loads. Indentation time: 10-15 seconds. Sample thickness ASTM: At least 10 .Application of Brinell Hardness Test. Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell method. As the Brinell test uses relatively high loads, and .

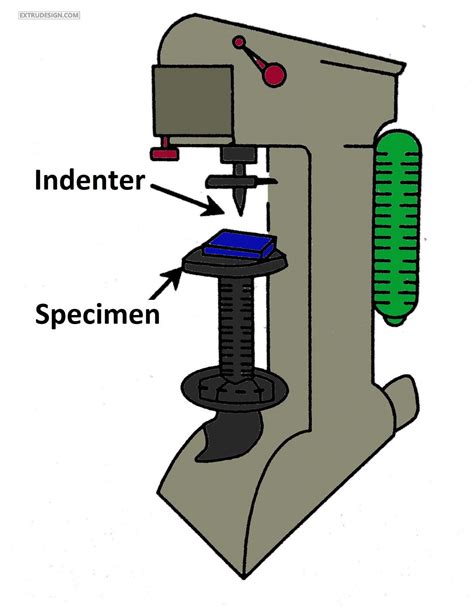

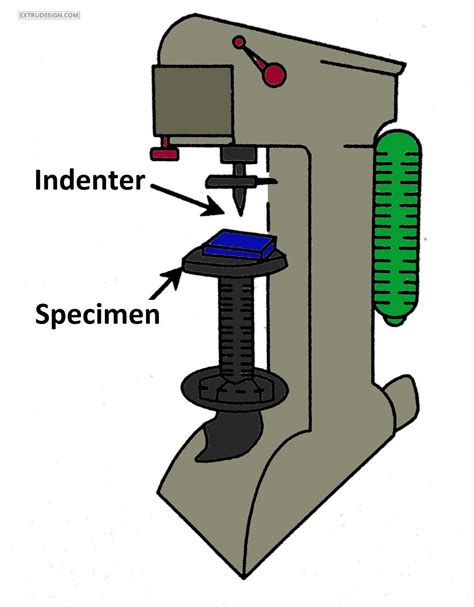

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel .

DEFINITION OF THE BRINELL HARDNESS TEST The Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His .Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate .The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

Brinell Hardness Test Procedure. The Brinell hardness test is a widely used method for assessing the hardness of materials. This chapter will outline the step-by-step procedure for conducting a Brinell hardness test, highlighting the key elements and considerations involved. 1. Preparation of the Specimen

Description of the Brinell hardness test showing the tester, the microscope for measurement and analysis using a spread sheet. The spreadsheet and SolidWork.Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the indentation is then .After the test, the preliminary test force is removed and the indenter is removed from the test specimen. Types of Rockwell Scale Table-1 below gives the information on the type of indenter, the magnitude of the major load, and common applications for each of the hardness scales as per ASTM standard E18 (1984). In the Brinell hardness test, we use a small ball (the indentor) made of tungsten carbide or steel to penetrate the material's surface, leaving a hemispherical indent. From the load/pressure on the indentor and the diameter of the hole it makes on the material surface, we can calculate its Brinell hardness number. .

The Brinell hardness test method follows ASTM E10 standards to inspect the materials whose structure is too coarse or having a rough surface such as castings and forgings. + 86 755 61301520; . Conducting a Brinell Hardness Test follows the guidelines in ASTM E10, which specifies its suitability for coarse-grained or rough-surfaced material . The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus . To conduct a compression test, you must use a standardized test specimen, ASTM E9 (1.0-inch diameter, and 2 inches in height), which is squeezed between the anvils of a compression testing machine. . What are the advantages and disadvantages of the Brinell hardness test? Advantages: It measures the hardness of a relatively large area .

manual compression test quizlet

In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide . (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity .The Brinell and Rockwell method uses diamond or steel ball indenters to conduct the hardness test on the test material. . The Brinell hardness test also uses a microscope to measure the indents made by the indenter. For this reason, the Brinell scale is more accurate than the Rockwell scale. However, using the Brinell hardness test method is .

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .Concluding a hardness test using a popular method like the Brinell hardness test requires measuring the indentation left on the material surface by the load applied. Though several other hardness testing methods are available, the Brinell hardness test and how to read and represent its values are why we’ve written this guide.Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known force. It’s suitable for materials with coarse grain structures or rough surfaces. . This method finds utility in scenarios where conducting a static hardness test (typically performed on a .

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to . https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.

Macro-Hardness (Rockwell and Brinell) testing is the most commonly applied materials test in industry due to several factors: 1) Macro-Hardness Testing is simple to perform and does not require highly skilled operators; 2) Through the use of different loads and indenters, hardness testing can be used for determining theStandard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is applied to the surface of the material for a longer duration, typically 15 to 60 seconds.To conduct a Brinell hardness test requires an indenter made from a hardened steel ball with a diameter of 10mm. The indenter applies a load range of 500kgf to 1,500kgf for soft materials but can apply as high as 3,000kgf for very large and thick materials. These loads are applied for 10 – 30 seconds, depending on whether the material is iron.ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .

brinell hardness testing procedure

WEBÍndice. Obtenha contas Blox Fruits Level Max gratuitas. Anuncios. ROBUX GRATUITO. Se você é fã de Blox Fruits, com certeza sabe que ter uma conta de nível máximo é .

how to conduct a brinell hardness test|brinell hardness testing procedure